In the process of manufacturing nuclear fuel, a powder lubricant is normally admixed and blended with granules of UO2 or Mixed Oxide like (U,Pu)O2 , (U,Th)O2 for continuous production of defect free green pellets in a multi-die cavity hydraulic press or multi-die Rotary powder compacting press. The admixed lubricant influences the sintering performance of these fuel pellets under hydrogen atmosphere as well as the furnace operation itself depending on its burn-out characteristics.

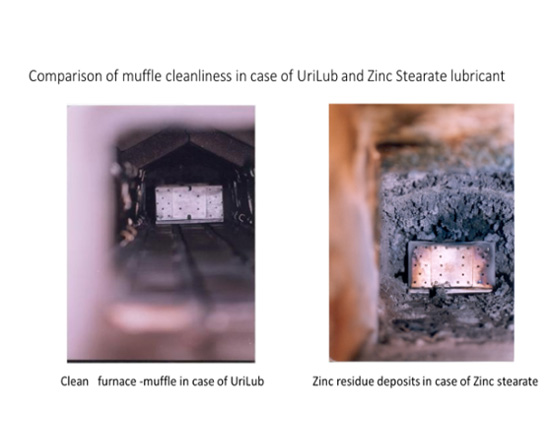

The conventional powder lubricant for compaction of these nuclear fuel is Zinc stearate. But fuel fabricators faced significant operational problems in the sintering furnaces. Zinc stearate does not burn-out cleanly and leave behind condensation of metallic zinc in the pre-heat section of the hydrogen atmosphere sintering furnace causing serious problems in its continuous operation and maintenance. Zinc deposition causes constriction of muffle interior, blockage of thermocouple ports and boat jamming. The sintering furnace requires periodic shut down cleaning and restarting that takes at least one-month cycle time. Fuel manufacturer incurs significant loss of fuel production and higher maintenance cost. Moreover, the zinc/zinc oxide bearing furnace off gas is health hazardous.

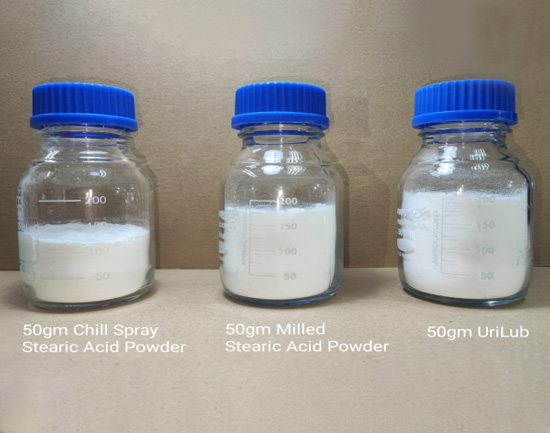

Nuclear fuel fabricators world-wide are researching on a suitable metalless powder lubricant as an alternative to zinc stearate. Hemo Asia Sdn Bhd takes pride in the successful development of superior grade, high purity organic powder for this unique application. UriLub (meaning Uranium Lubricant) is a trade name of this high performance fully organic lubricant consisting of specially formulated, extremely fine and favorable shaped stearic powder. An advanced innovated milling technology is adopted to achieve this morphology. Because of its low bulk density (about 0.12g/cm3), bigger surface area, and higher spreadability, the lubricant particles spread evenly to the UO2 granule surfaces for better uniform admixing. The lubricant provides optimal lubricity with only a small quantity admixing (0.25to 0.30 wt%) to minimize die-wall friction as well as UO2 inter particle friction resulting into similar green density. At the same time, it provides fuel particles bonding resulting into high speed un-interrupted defect free pellet production. Unlike zinc stearate, UriLub completely volatilizes at about 400 deg C as against 1050 deg C for zinc stearate (as observed in Thermo-Gravimetry Analysis) under hydrogen atmosphere. Hence fuel pellets are de-lubricated at a much lower temperature keeping the furnace interior clean and devoid of any residue accumulation. Furnace off gas is harmless and environment friendly unlike zinc stearate. Moreover, it is observed that under similar sintering condition, the fuel pellets sinter to 0.04 to 0.05g/cc higher sintered density than zinc stearate lubricated pellets. This is significant for PHWR fuel.

Successfully developed and proven in operation in Nuclear Fuel Fabrication in India since 2003, Hemo Asia Sdn Bhd is ready to provide guidance and assistance on UriLub application.

We have in-house, a Nuclear Lubricant specialist with more than 20 years experience on various admixed Lubricant blending with UO2 granules, compaction of green pellets in hydraulic, rotary press and sintering of UO2 fuel pellets.

Our specialist is available to answer and assist any queries on UriLub admixed lubricant, technical issues and also provide step by step guidance and assistance for the successful adoption of UriLub in the compaction UO2 green pellets in your plant.

Comparison between Common Fatty Acid and UriLub

Do not hesitate to contact us at hemoasia@hemoasia.com.my for your enquiries.