TriStar Stearic Acid Powder is derived from 100% RSPO Palm Oil. The Stearic Acid Powder is produced using a propriety milling technique which produce a fluffy amoeba snow flake powder with very low bulk density and the highest surface area. This characteristic translates to maximum spreadibility and dispersion, a major factor in pharmaceutical/ nutritional tableting operation.

There are two ways to produce Stearic Acid Powder ie. i) By milling, ii) By Chill Spray. Stearic Acid Powder produced by these 2 methods may look the same and even having similar mesh size, however their performance VARY significantly.

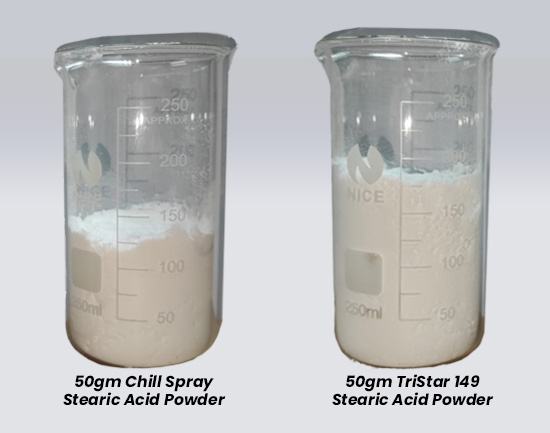

TriStar 149 Milled Stearic Acid Powder Vs Chill Spray Stearic Acid Powder of similar Mesh Size

Why Choose TriStar 149 Stearic Acid Powder?

As seen in the photograph above, SAVINGS of more than 30% (by weight) is achieved when switching from Chill Spray Stearic Acid Powder to TriStar 149 Milled Stearic Acid Powder without sacrificing quality. More important, better quality tablets are produced with lower dosage.

Insist on Milled Stearic Acid Powder, Insist on TriStar 149 Stearic Acid Powder.

Mesh size may be the same however bulk density varies significantly between Milled Stearic Acid Powder and Chill Spray Stearic Acid Powder.

| Product | Bulk Density gm/cc |

|---|---|

| TriStar 149 Stearic Acid Powder | 0.261 |

| Chill Spray Stearic Acid Powder | 0.387 |

| Bead Stearic Acid | 0.522 |

| Zinc Stearate | 0.288 |

| Magnesium Stearate | 0.256 |

*Zinc or Magnesium Stearate will not liquefy completely at 60 - 65°C. This will create abrasion leading to higher wear and tear. Further Zinc or Magnesium Stearate is hygroscopic in nature leading to tablet discolouration over time. Stearic Acid Powder on the other hand melts completely at 60-65°C and resolidify at temperature less than 55°C. It is also non-hygroscopic leading to better shelf life of tablets. *

| Tristar 149 Milled Stearic Acid Powder | Chill Spray Stearic Acid Powder | Preference | |

|---|---|---|---|

| Bulk Density - gm/cc |

Lower - 0.2610 | Higher - 0.3870 | Tristar 149 |

| BET Surface Area - m²/gm |

Higher - 3.5375 | Lower - 2.5460 | Tristar 149 |

| Volume - cc/gm |

Higher - 3.8314 | Lower - 2.5840 | Tristar 149 |

| Feel | Soft Fluffy | Compact | Tristar 149 |

Tristar outperform Chill Spray Stearic Acid Power in every aspect. Switch to Tristar 149 for better quality products at lower cost. Savings of more than 30% is achievable.

Not Convinced! Test it yourself. Contact your nearest Tristar representative for samples of Tristar 149. Weigh 50grams of Tristar 149 and 50grams of your present Chill Spray Stearic Acid Powder and pour them into a beaker of similar size. You will be amaze to see the difference.

APPLICATION

Stearic Acid Powder is a Non-Active Pharmaceutical Ingredient (non-API). It does not have any medicinal value. It is used as an excipient/lubricant to facilitate the production of tablets. As such MINIMUM amount possible should be used.

TriStar Stearic Acid Powder is used as an excipient / lubricant in pharmaceutical and nutritional tableting. It prevents clumping and sticking to die punches ensuring smooth ejection of tablets. Minimal amount should be used to avoid agglomeration lamination and picking issues.

In cosmetics, use of TriStar Stearic Acid Powder reduces processing time to homogenise formulation.

TRISTAR STEARIC ACID POWDER TYPE 50 RSPO-MB

Colour: White or yellowish white

Appearance: Soft fluffy powder

Stearic Acid, C18 %: 50 min

Palmitic Acid, C16 %: 42 min

Combination of C16 & C18 NOT LESS THAN 90% min

Compliance: USP/NF, EP, BP, JP, ChP, Kosher, Halal Produced in FDA audited factory.

Packing Standard: 20KG Paper Carton with food-grade HDPE bag

TriStar is a tested lubricant offering functionality during direct compression of compound or granulates of Active Ingredients. (wet or dry granulation) It has been tested on Acetaminophen, Aspirin, ibuprofen and Vitamin C.

TriStar enhances tableting process because of its special properties. A much smaller dosage is used without sacrificing quality. It has a Titre (Melting Point) of 53 -59 Deg C. Because of its smaller dosage, during tableting as the mixture is compressed TriStar liquefies for a brief moment and as it re-solidifies it contracts sightly and promptly release the table from the punch. Agglomeration and picking are avoided. This creates a highly desirable hard and glossy finished tablets.

As TriStar Stearic Acid Powder is non-hygroscopic, tablets will not have issues of discolouration normally associated with tablets using Magnesium / Zinc Stearate.

TriStar has shown great improvement over other lubricant on preventing picking, lamination or capping. It has also proven to extend production by preventing excessive wear on machinery. It is the ONLY lubricant tested that have shown absolutely NO reaction with acid “actives” such as Ascorbic Acid, or Acetylsalicylic Acid.

We use a special blend of fatty acid. It has no soapy taste and improve the smoother mouth feel for chewable of acidic “Actives”.

TriStar Stearic Acid Powder is produced in a dedicated factory to avoid cross-contamination.

OTHER BENEFITS ASSOCIATED WITH TRISTAR STEARIC ACID POWDER

TriStar is manufactured in a dedicated facility under full GMP condition, With both cGMP and ISO Certification. Facility has been audited and passed by US FDA.

No animal testing is used in the production of this product.

Contact us for further information.

Eliminate wastages and Costly problems by switching to TriStar.

TriStar is produced by Hesego Industry Sdn Bhd (ISO/ GMP/ RSPO certified) a subsidiary of HEMO ASIA SDN BHD.